News

Wagnermaier, specializing in production of semitrailers with the localized assembly factory, concluded a firm contract with Accuride Corporation, a giant of wheel systems industry. This strategic partnership provides for expansive supplies of top-quality products for Wagnermaier semitrailers.

Having the production capacity of 3 000 machinery items annually and startup investments of about 745 MIO RUB, Wagnermaier Russland LLC sets new standards in semitrailers industry. Signing of a major supply contract for 10 000 product items in 2024 certifies the certainty and high potential of the company’s growth.

Accuride Corporation is known for its unparalleled quality as a manufacturer of steel and aluminum wheel disks and of various components and units for wheel systems of commercial vehicles. Cooperation of these two major players clearly provides new prospects for both companies.

If suppliers conclude a firm contract with Wagnermaier, they will have an opportunity to efficiently manage their stock reserves and to optimize the whole supply chain, provided that they meet the deadline. This unique approach does not have any parallel among other manufacturers of semitrailers which adhere to principles of situational purchases.

«Accuride Corporation is tremendously pleased to start the cooperation with Wagnermaier. This partnership is not just a business interaction for us; it is an opportunity to unite forces of two technically advances companies with the purpose of improving the quality and bringing the reliability of transport solutions to the next level. We are happy that our wheel disks will be a part of Wagnermaier products, ensuring meanwhile high efficiency and safety of semitrailers», – noted Kirill Katyshev, the executive director of Accuride Wheels Russia LLC.

«On behalf of Wagnermaier I want to express gratitude to Accuride for our efficient partnership and mutual understanding. Accuride is a company which goes back centuries. Apart from everything else it has experience in supplying products for many European manufacturers including but not limited to Volvo. This brand is famous for its unequalled standards. Surely that speaks volumes. We are actually glad that this cooperation went through. Accuride is well informed about our requirements and necessities in products. These matters were taken into account when setting the manufacturing plan. Moreover, we fixed prices and scope of supplies for coming periods», – noted Rustam Subkhankulov, the executive director of Wagnermaier Russland LLC.

Wagnermaier proudly announces the signing of a contract with Trading company “Kama”, the general distributor of КАМА TYRES, which products are famous for their high quality and innovative technologies.

Wagnermaier Russland LLC, deservedly holding its market positions because of the uncompromising combination of reliability, functionality and modern technological solutions in the sphere of manufacturing semitrailers, chose tires manufactured by КАМА TYRES as the best option for making a complete set of its products.

On the terms and pursuant to the conditions set out in the contract Trading company «Kama» will ensure the supply of 10 000 items of top-quality tires for making a complete set of semitrailers manufactured by Wagnermaier, confirming hereby its positions of a leading manufacturer at the tires market. This interaction method, as provided for by a firm contract, helps the organization to scale down stock reserves and to cut costs through optimizing all supplies, which become stable and systematic, and promotes more efficient management of the supply chain.

For 25 years now Trading company «Kama» successfully sells КАМА TYRES products at the Russian and international markets. Trading company «Kama» is one of the largest distributors of tires in Russia. Assortment of the enterprise includes more than 500 product items. Quality of sold tires, wide range of products, and professional approach of KAMA TYRES will help to set a new standard for parameters of safety, longevity and economic operational efficiency of semitrailers manufactured by Wagnermaier.

«We sincerely thank Kama for the vested confidence and efficient interaction. We reckon upon the continuation of our partnership on a long-term basis. Work with KAMA TYRES is a considerable achievement. Their tires are ideal for the linehaul machinery. Our semitrailers were tested exactly on these tires. We succeeded not only in the effective cooperation with Trading company «Kama» but also in fixing the scope and prices for future periods», – communicated Rustam Subkhankulov, the executive director of Wagnermaier Russland LLC.

«Tires, manufactured by KAMA TYRES, will make its contribution to the durability of modern Wagnermaier semitrailers. Our products satisfy the requirements of freight forwarders to wear-resisting properties and economic operational efficiency because of application of top-quality materials, structural reliability and long operational lifetime. We are proud to become a part of such an ambitious project as manufacturing Wagnermaier semitrailers», – communicated Timur Sharipov, the executive director of Trading company «Kama».

All-steel tires 385/65 R22.5 КАМА NT 202 will be supplied within the framework of the contract. This model is designed and suitable for being operated at the mounted axle of cargo trailers and semitrailers used for local and regional cargo transportations. Improved bonding parameters and increased tread wear resistance are insured by renovated rubber mix components used when manufacturing the tire. Aquaplaning resistance is ensured via three deep passages for cleaning the tread and removing water from the flat spot. Increased road stability and skid resistance are ensured via the intensified shoulder area of the tread. Resistance to damages and blowouts is ensured via the intensified central part of the tread.

The first serial semi-trailers (curtain- and drop-sided, tri-axle, of standard European length) came off the conveyor of the machine-building complex in «Alabuga». A semi-trailer WAGNERMAIER CRS3 FOR A LONG TIME with an available body space of 92 cub. m is capable of carrying cargos of up to 32 500 kg in weight. Notice that its unladen weight is 6480 kg. Warranty for all units and components of the semi-trailer is three years fr om the moment of sale without any haulage lim it.

Constructional and technological solutions make semi-trailers of Wagnermaier reliable, durable and economically efficient in case of the long-term operation. The main feature of semi-trailers is a rugged frame of the patented structure: with solid longitudinal side-members without welded joints. The gooseneck part of the frame has two walls. This structure significantly reinforces the zone of the fifth-wheel coupling of the device and prevents the deformation of the forepart of the frame under the weight of the fore wall. The production of the frame at the Wagnermaier Factory is completely localized (from laser metal cutting and painting to assembling on holding frames). The whole metal part, drop sides, rear bump stop are also made locally.

Only high-strength steel is used for production: side-member is of steel grade Magstrong / Powerweld S700, attachable parts are of steel Powerform 420. This gave an opportunity to achieve the weight perfection: the frame weighs only 2200 kg. Notice that the total laden weight of the semi-trailer is 6480 kg. Thorough processing of the semi-trailer before painting and high-quality covering of the frame protect the structure from corrosion and thereby extend the service life of the semi-trailer.

All attachable equipment of the semi-trailer is made by the world leaders. Axles (SAF Intra Custom Design), tested by the long-term service, are designed and suitable for working on bad roads. Brake control system (Wabco EBS Premium) has an antiskid function. All other components are also of well-known brands: electrical parts are of Aspoeck, roofs are of Edscha, side columns are of Adaico, fittings for tilts, gates and drop sides are of Hestal. Curtains are made of the reinforced PVC-fabric of Mehler. Tilt, made of this fabric, is light, elastic and rigid. It is difficult to tear, wear and break it even in freezing temperatures.

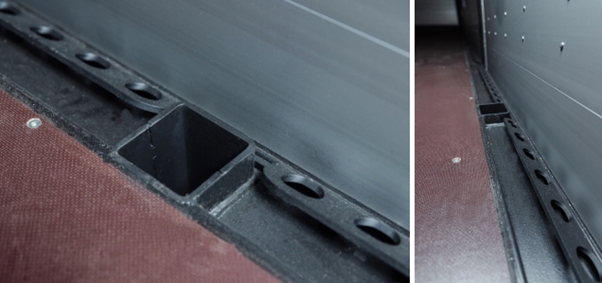

A robust chassis of the semi-trailer WAGNERMAIER CRS3 FOR A LONG TIME is equipped with an inventive system WM-Lock, which ensures the multi-pointed belt anchorage to the outer frame. There are 352 different points of anchorage (176 points on each side). This makes the cargo securement system flexible and ensures the high safety level when transporting cargo. It is convenient for the driver because it will be not necessary for him/her to open the drop side of the semi-trailer or to remove the tilt for anchoring the cargo.

The floor supported by side-members is one more efficient solution from Wagnermaier. Usually the cargo-carrying floor in semi-trailers consists of three parts. It means that they are supported not by side-members (the most robust load-bearing elements of the frame structure), but by cross-arms. This fact degrades load-bearing characteristics of the floor and decreases the cargo-carrying capacity of the semi-trailer.

The floor in semi-trailers of Wagnermaier is solid. Elements of the floor covering lie on side-members as a solid plate (from the right drop side to the left drop side) and cross-arms, which hold it, go under the upper cap of the side-member. This configuration is not easy: it is more complicated and more expensive to manufacture cross-arms with such section. Moreover, it is necessary to take measures for ensuring that the floor thickness will not affect the useful capacity of the semi-trailer interior. For this the height of side-members is decreased. It is possible due to using the high-strength steel.

The fore wall of the semi-trailer body is also an important structural element. To protect the driver and to prevent the damage by the loader fork, the aluminum section of the wall is reinforced with a steel sheet of 3 mm in thickness.

Before the beginning of the serial production, the prototype of the semi-trailer was tested during several months at the track of Central Scientific Research Automobile and Automotive Engines Institute. Conditions were very severe, like a crash-test: 12 types of tests with the acceleration factor 14:1 (i.e. 1 km of haulage at the track corresponded to 14 km of the real service on the road).

Two sets of tires were worn during tests. It is equal to 500 000 kilometers travelled. The semi-trailer was loaded with the cargo of almost 35 tons, and it was working strenuously at the most difficult sites of the track: the Belgian pave with inequalities of threshold nature and the limited speed, on the mountain road (this section is designed for running tests of reliability and longevity under extra strain on units of transmission and braking systems). Crash-tests proved the structure reliability and a long useful life of the semi-trailer. Testers tried but finally did not succeed in breaking it.

On January 31, 2024 a machine-building complex Wagnermaier was ceremonially opened in the territory of the technical park «Synergy» (Special Economic Zone «Alabuga», Tatarstan). Rustam Minnikhanov, the Head (Rais) of the Republic of Tatarstan, Rustam Subkhankulov, the executive director of «Wagnermaier Russland», partners and suppliers of the factory, representatives of mass media participated in the event.

Wagnermaier is a joint venture with a leading European manufacturer of linehaul machines. Partners implements in Russia a project for the production localization of tilt-covered semi-trailers according to the European technology. Aleksandr Shmidt, the technological consultant of the project, responsible for consistency control of semi-trailers Wagnermaier with stringent European standards, noted: «Production implementation of such level in Russia was a challenging task. However, despite all happenings of past years, we believe in the Russian market and that we are able to find a niche here».

A limited series of 25 semi-trailers with a special livery was produced in honor of opening the production of Wagnermaier. This livery shows the timeline of stages of large investments by German companies in the Russian economy during the period from 1852 to 2023.

Over the years the European brands of tilt-covered semi-trailers in Russia occupied more than a half of the whole market. When they left the market because of sanctions, the segment faced the deficit: there are not enough domestic products, orders are scheduled for months and years ahead. Evgenii Popravka, the director of Полуприцеп.рф Company (an exclusive distributor of Wagnermaier in Russia and CIS countries), provided the branch-wise statistics:

«In 2021 in sales of Cargo carriers semi-trailers 56% were occupied by manufacturers from the European Union and 37% were occupied by the Russian manufacturers, respectively. In 2023 the share of the Russian companies grew up to 65%, and the share of manufacturers from the European Union dropped to 18% (the remaining 17% were occupied by products from friendly countries). Machines of the European brands are still present at the Russian market and even have a notable share, but they all are supplied under the parallel import scheme. However, this logistics is complicated. The price of semi-trailers becomes significantly higher along the way, but anyway they are still in demand because of the deficit in offer from domestic manufacturers and the demand for the European quality, which is in demand among the Russian cargo transportation companies. At the same time over the past five years, regardless of the pandemics and sanctions, the market of semi-trailers has significantly grown up. There is a reason for this: about 1,2 mln of semi-trailers are registered in Russia, their average age is 22 years, while the forecasted useful life of these machines is nine years. Whereby 70 percent of the total quantity, and this is 800 thousand semi-trailers, is older than 12 years. Production capacities of all domestic manufacturers allow to upgrade this out-of-date fleet in full only after 20 years. During this time machines will get out of date once again. That is why there is a real request from the sector to launch new production sites».

There are about 1,2 mln of semi-trailers registered in Russia (as of January 2023), and 70% of them are machines older than 12 years

Rustam Subkhankulov, the executive director of «Wagnermaier Russland», commented the production localization project and told about plans of its further development: «An official opening of a machine-building complex is only a first step. In the nearest time we plan to start the around-the-clock work and to reach the project capacity of three thousand semi-trailers per year. The production is focused on the output of only one type of semi-trailers. It is compact, automated and high-performance. This limitation in nomenclature ensures a persistently high quality standard, and this is also the European attitude towards the production. Wagnermaier is the only factory in Russia, which specializes in producing only tilt-covered semi-trailers. It means that the factory outputs only one model and two body sizes: of the standard European length (13,6 meters) and with the elongated (up to 16,5 meters) platform. The last semi-trailer is designed and suitable especially for cargo transportation inside Russia. The increase of the production localization share is also an important issue for us. In perspective it shall reach 75%. For this we launch joint development projects with the Russian partners. Now we have six R&D activities related to the localization: production of the sliding roof, landing gear and composite bump stop, LED lamp, ladder and side columns».

Machine-building complex Wagnermaier began working in the territory of the country’s largest industrial cluster «Alabuga», located in Tatarstan. It is a localized production of semi-trailers, which are manufactured according to the European technology

Wagnermaier Company is created within the framework of a joint venture with a leading European manufacturer of linehaul machines. All production in «Alabuga» (from selected suppliers of equipment and components to equipping the workplaces) is carried out according to international standards. Wagnermaier Factory in Russia is focused on tilt-covered semi-trailers. It is a compete production cycle: from manufacturing a frame of high-strength steels to assembling the attachable equipment and the superstructure.

«Cargo transportation companies are accustomed to the European machines, there is a demand for a premium quality at the Russian market, — noted Rustam Subkhankulov, the executive director of «Wagnermaier Russland». — Semi-trailers of Wagnermaier are equipped with components and devices, well-known both by transportation companies and car service centers, — such as axles of SAF, modulators of Wabco, electrical parts of Aspoeсk, sliding roofs of Edscha».

Semi-trailers of Wagnermaier are the embodiment of reliable structural and technological solutions, created by engineers of the European research and development center. Innovative solutions of Wagnermaier (including the rugged frame, solid floor supported by side-members, ergonomic cargo securement system WM-Lock) are patented.

Complete production cycle

The territory of the machine-building complex Wagnermaier is a big production module of 7 500 square meters in area with an open yard for storing machines. The enterprise was placed in the ready premise «Synergy Heavy», built by Special Economic Zone «Alabuga». The decision to place the production here rather than elsewhere was supported with not only logistic and infrastructural advantages, but also with a series of economic factors: «Alabuga» offered the lowest profits tax and an opportunity to import the foreign equipment, without paying VAT. Due to the fact, that Wagnermaier Company succeeded in renting the ready module, rather than a construction site, the production was launched only within one year and a half.

Pre-commissioning activities at the factory were finished in August 2023. The automated hi-tech equipment was placed in a spacious shop. The staff was selected and trained. The enterprise will employ 250 persons in total. It is a satisfactory figure for a modern machine-building enterprise, which plans to work on a three-shift basis (round-the-clock). The proficiency of employees and the equipment of shops with robots and modern holding frames ensure the high gross income per one employee (more than 50 mln rub per year). The salary of employees will exceed the market average salary by 25%.

The production site is equipped with lines for preparing metal structures, welding, painting, assembling and checking quality before shipping. There are 24 sites in total. All workplaces are included in the unified production management system, tracking online the stock balance, cost of each unit, operating efficiency of each employee.