Novelty from Wagnermaier: a curtain semi-trailer

The first serial semi-trailers (curtain- and drop-sided, tri-axle, of standard European length) came off the conveyor of the machine-building complex in «Alabuga». A semi-trailer WAGNERMAIER CRS3 FOR A LONG TIME with an available body space of 92 cub. m is capable of carrying cargos of up to 32 500 kg in weight. Notice that its unladen weight is 6480 kg. Warranty for all units and components of the semi-trailer is three years fr om the moment of sale without any haulage lim it.

Constructional and technological solutions make semi-trailers of Wagnermaier reliable, durable and economically efficient in case of the long-term operation. The main feature of semi-trailers is a rugged frame of the patented structure: with solid longitudinal side-members without welded joints. The gooseneck part of the frame has two walls. This structure significantly reinforces the zone of the fifth-wheel coupling of the device and prevents the deformation of the forepart of the frame under the weight of the fore wall. The production of the frame at the Wagnermaier Factory is completely localized (from laser metal cutting and painting to assembling on holding frames). The whole metal part, drop sides, rear bump stop are also made locally.

Only high-strength steel is used for production: side-member is of steel grade Magstrong / Powerweld S700, attachable parts are of steel Powerform 420. This gave an opportunity to achieve the weight perfection: the frame weighs only 2200 kg. Notice that the total laden weight of the semi-trailer is 6480 kg. Thorough processing of the semi-trailer before painting and high-quality covering of the frame protect the structure from corrosion and thereby extend the service life of the semi-trailer.

All attachable equipment of the semi-trailer is made by the world leaders. Axles (SAF Intra Custom Design), tested by the long-term service, are designed and suitable for working on bad roads. Brake control system (Wabco EBS Premium) has an antiskid function. All other components are also of well-known brands: electrical parts are of Aspoeck, roofs are of Edscha, side columns are of Adaico, fittings for tilts, gates and drop sides are of Hestal. Curtains are made of the reinforced PVC-fabric of Mehler. Tilt, made of this fabric, is light, elastic and rigid. It is difficult to tear, wear and break it even in freezing temperatures.

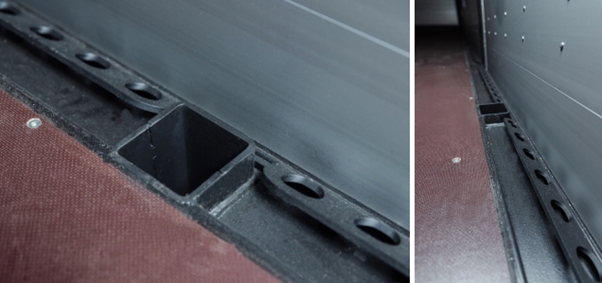

A robust chassis of the semi-trailer WAGNERMAIER CRS3 FOR A LONG TIME is equipped with an inventive system WM-Lock, which ensures the multi-pointed belt anchorage to the outer frame. There are 352 different points of anchorage (176 points on each side). This makes the cargo securement system flexible and ensures the high safety level when transporting cargo. It is convenient for the driver because it will be not necessary for him/her to open the drop side of the semi-trailer or to remove the tilt for anchoring the cargo.

The floor supported by side-members is one more efficient solution from Wagnermaier. Usually the cargo-carrying floor in semi-trailers consists of three parts. It means that they are supported not by side-members (the most robust load-bearing elements of the frame structure), but by cross-arms. This fact degrades load-bearing characteristics of the floor and decreases the cargo-carrying capacity of the semi-trailer.

The floor in semi-trailers of Wagnermaier is solid. Elements of the floor covering lie on side-members as a solid plate (from the right drop side to the left drop side) and cross-arms, which hold it, go under the upper cap of the side-member. This configuration is not easy: it is more complicated and more expensive to manufacture cross-arms with such section. Moreover, it is necessary to take measures for ensuring that the floor thickness will not affect the useful capacity of the semi-trailer interior. For this the height of side-members is decreased. It is possible due to using the high-strength steel.

The fore wall of the semi-trailer body is also an important structural element. To protect the driver and to prevent the damage by the loader fork, the aluminum section of the wall is reinforced with a steel sheet of 3 mm in thickness.

Before the beginning of the serial production, the prototype of the semi-trailer was tested during several months at the track of Central Scientific Research Automobile and Automotive Engines Institute. Conditions were very severe, like a crash-test: 12 types of tests with the acceleration factor 14:1 (i.e. 1 km of haulage at the track corresponded to 14 km of the real service on the road).

Two sets of tires were worn during tests. It is equal to 500 000 kilometers travelled. The semi-trailer was loaded with the cargo of almost 35 tons, and it was working strenuously at the most difficult sites of the track: the Belgian pave with inequalities of threshold nature and the limited speed, on the mountain road (this section is designed for running tests of reliability and longevity under extra strain on units of transmission and braking systems). Crash-tests proved the structure reliability and a long useful life of the semi-trailer. Testers tried but finally did not succeed in breaking it.

Polupricep.rf Company is an exclusive distributor of Wagnermaier brand in the territory of Russia and CIS countries. Semitrailers are available for being purchased in the form of an operating lease or a lease with an option to buy and are accompanied with a service contract, comfortable for cargo transportation companies.