About company

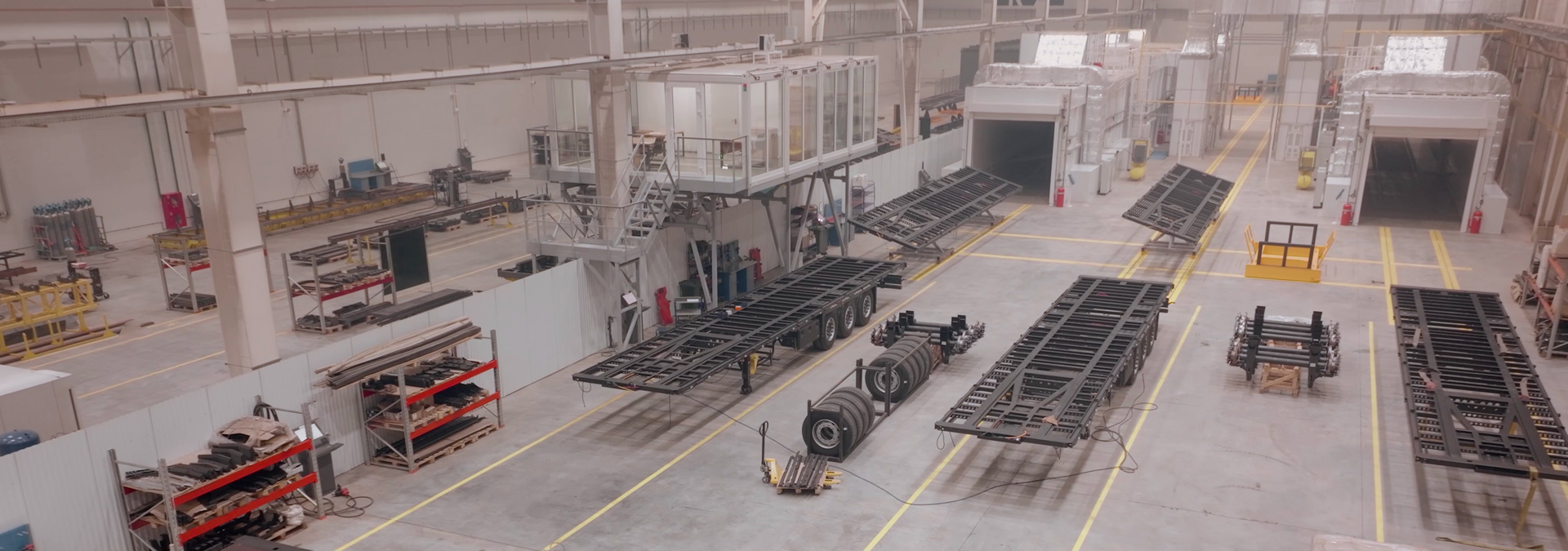

Output of machines is organized on a new production line in the territory of the special economic zone Alabuga which is the largest industrial cluster in the country located in the Republic of Tatarstan. The line is fitted out with the high-tech equipment for assembling and painting semitrailers.

To ensure the uninterrupted production process, Wagnermaier company forms a list of top-priority Russian suppliers of products from European brands i.e., top-quality parts and components meeting rigid criteria of durability, reliability, and longevity.

Engineering solutions and modern production technologies make Wagnermaier semitrailers reliable, longeval and economically efficient with prolonged operation – the low cost of a kilometer in the way.

WHAT DO WE DO

using top-quality assemblies and components:

WHY DO

CARRIERS

SELECT WAGNERMAIER

WHY DO

CARRIERS

SELECT WAGNERMAIER

WHY DO

CARRIERS

SELECT WAGNERMAIER

WHY DO

CARRIERS

SELECT WAGNERMAIER

WHY DO

CARRIERS

SELECT WAGNERMAIER

WHY DO

CARRIERS

SELECT WAGNERMAIER

WHY DO

CARRIERS

SELECT WAGNERMAIER

2. Zinc-containing primer

3. Painting with enamel

2. A load of 35.5 tons

3. Operations in 3 shifts

EQUIPMENT

The planned useful life of the line-haul Wagnermaier semitrailer is intended for the term from fifteen years. Quality standards are certified with the 20-year warranty on the perforation corrosion on the frame.

To implement the European production technology, the line is fitted with the high-tech equipment of the largest world manufacturers, leading in their segment. All installations for laser cutting, welding, surface treatment and application of long-life coatings were designed in strict accordance with special requirements.

The central part of the production line is for producing the bearing frame. Technical characteristics of the bearing frame set basic operational capabilities of the semitrailer.

The company demands higher standards of the structural strength of its frames. That is why frames are made of high-tensile steel of premium quality. The company independently designs the technological tooling used for positioning integral parts of the frame when assembling it. Using high-tensile steel gives an opportunity to reduce the unladen mass of the semitrailer and at the same time to increase the weight of the transported cargo without violating weight-checking norms.